Speed, precision and productivity cannot be compromised in contemporary manufacturing. Of all the technologies that are changing the manufacturing landscape, fibre laser cutting machines are those that are making the difference. Be it auto firms or aerospace and even electrical industries, these machines are revolutionizing the cutting, shaping, and production of high-quality components.

If you want to know about how new laser cutting machines are helping with efficiency, then this blog will walk you through the whys of why fibre laser cutting machines are the new industrial gold standard of cutting.

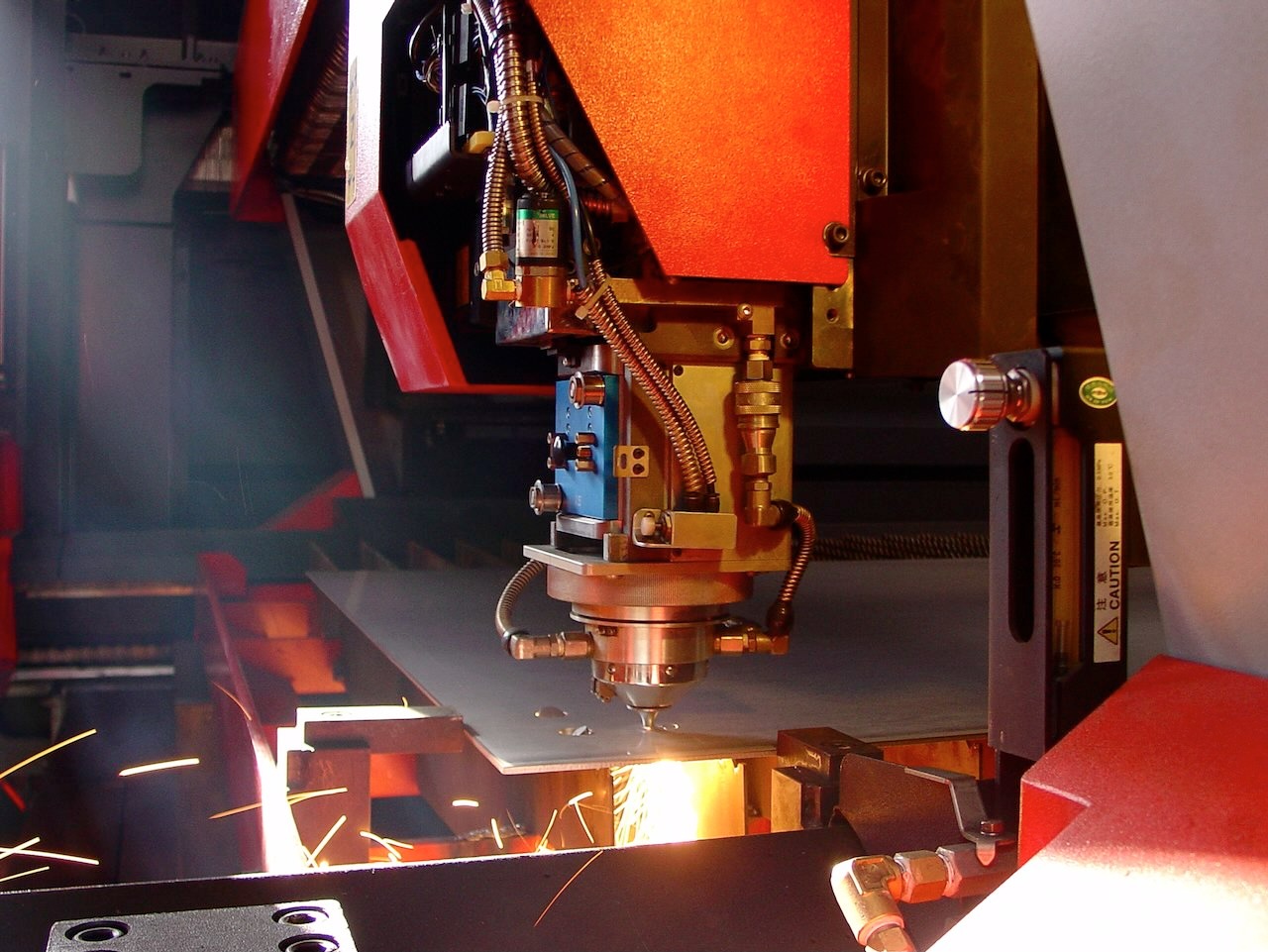

A fibre laser cutting machine is a solid-state laser-laser cutter that is laser-based using optical fibre to create a high-energy beam. Unlike CO₂ lasers, which have support via lenses and mirrors, fibre lasers propagate the laser beam through flexible fibre optics, thus making them light-weight, efficient, and low-maintenance.

These devices are especially helpful in cutting metals into sheets, tubes, and even thin strips of stainless steel, aluminium, copper, and brass. With their high accuracy and energy-saving usage, these days they are the most popular option for most industries.

The strongest case for a laser cutting machine is that it can create extremely accurate cuts with limited waste of material. Fibre laser cutting machines are able to cut to a tolerance of ±0.01 mm. That level of precision is required by manufacturers who need exact specification, i.e., aircraft parts and medical equipment.

Apart from that, fibre lasers are quicker than CO₂ lasers, particularly when cutting thin materials. Increased speed improves productivity and allows products to be manufactured under stringent schedules without compromising quality.

In the case of CO₂ laser cutting machines, fibre laser cutting machines consume less energy. They consume on average 30% less energy, and the same is in proportion to lesser electricity bill as well as lesser carbon footprint. Besides this, as they have less moving parts and no gas for the production of the laser, maintenance is minimal..

Overall, for cost-effective or eco-friendly manufacturing processes, a fibre laser cutting machine is an investment that is worth every penny.

From razor-thin foils of stainless steel to thick aluminium or titanium metal plates, fibre laser cutting machines are completely flexible. They are ideally suited for cutting metals that are otherwise difficult to cut using other lasers.

This versatility to cut various materials allows companies to increase their customer base and receive orders of their choice without multiple cutting systems.

Automation and smart solutions are the way forward with the Industry 4.0 transition. The majority of laser cutting machines employed today are automation-ready, i.e., robotic arm compatible, material handling system compatible, and CNC controller compatible.

Fiber laser cutting machines can be remotely monitored, data is accessed, and on-line adjustment is feasible, thus paving the way for digital manufacturing environments.

Conventional cutting methods, say plasma or flame cutting, generate a high heat-affected zone that degrades the material's integrity and requires further processing. Fibre lasers generate an ultra-skinny beam that cuts with minimum thermal distortion.

This equates to smoother edges, less burr, and fewer finishing operations - time- and man-power-saving.

Use Cases by Industry

Automotive: Cutting car body frames, exhaust systems with customised design, and brackets

Aerospace: High-precision components of aluminium and titanium

Electronics: Micro-cutting for circuit boards and enclosures

Construction: Metal doors, window frames, structure components

Medical: Surgical instruments and customised implants

All these industries fall under the speed, precision, and cost-effectiveness of fibre laser cutting machines.

Manufacturing companies cannot continue to be the same with changing demands and the rise in competition. An upgrade to better machines like the fibre laser cutting machine is no longer a choice, it's a necessity.

Whether as a metal fabricator, an original equipment manufacturer, or a prototype production house, it is an investment in a laser cutting machine that promises not only better results, but long-term business success.

If your factory is not yet advanced, it is time to find the wonderful benefits of fibre laser cutting technology, accuracy and productivity.