Bending

Bending Rolls

Bevelling

Boring

Broaching

Circle Cutters

Coil processing

Deburring

Drilling

Electro Discharge Machining

Engraving and Marking

Face and Centering Machines

Finishing

Folding

Forging

Gears Machining

Grinding

Guillotines

Honing

Ironworkers

Lapping

Laser Cutting

Lasers Profiling

Lathes (CNC and Manual)

Levelling

Machining Centres

Milling

Notching

Planing

Plasma Cutters

Polishing

Press Brakes

Presses

Profile Cutters

Punching

Rivetting

Roll Forming

Rolling Mills

Routing

Sawing

Shotblasting

Slitting Lines

Slotting

Steel Workers

Straightening

Swarf Conveyors

Tapping

Thread Rolling

Transfer

Tube Bending

Waterjet Cutting

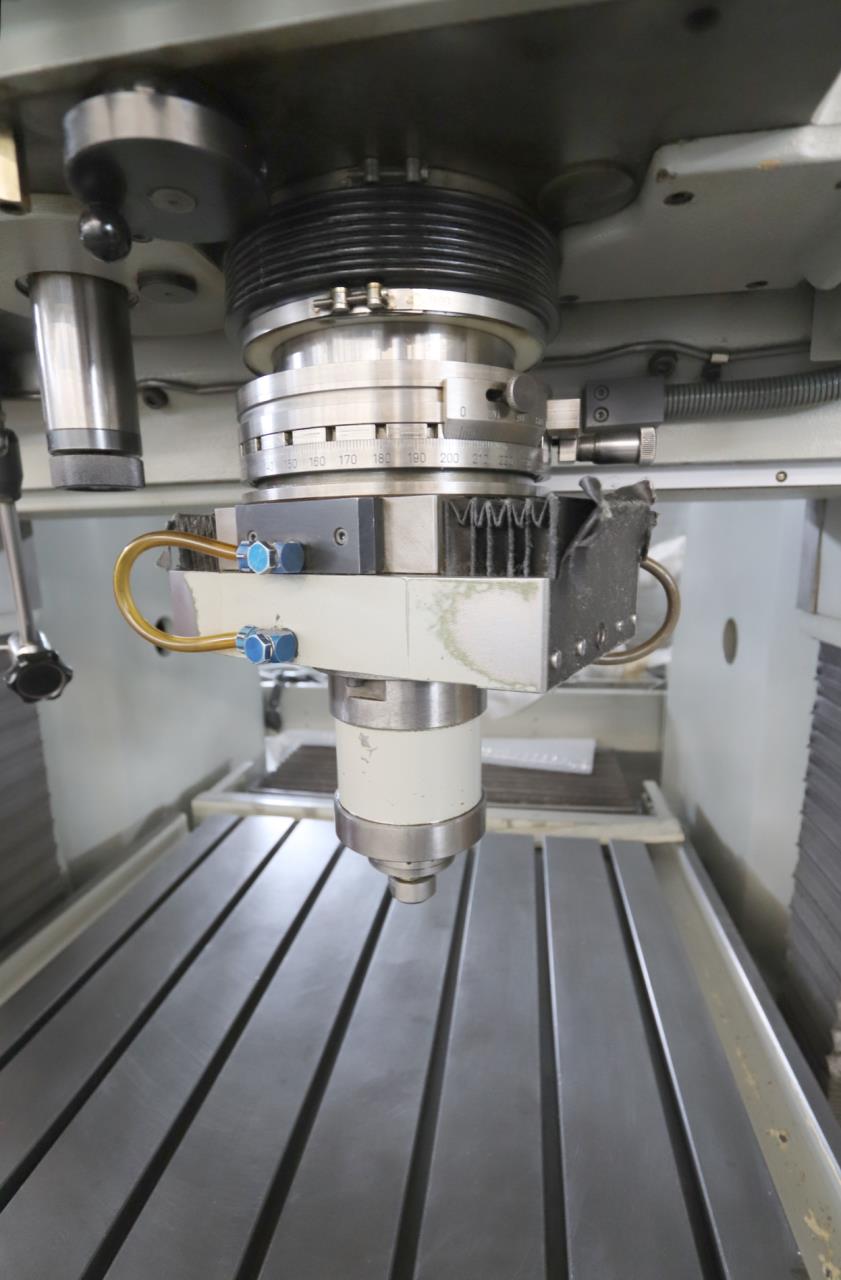

MACHINE INFORMATION AND SPECIFICATION

- Category:

- Grinding

- Subcategory:

- Jig Grinders

- Manufacturer:

- Hauser

- Model:

- HAUSER S 50 DR

- Condition:

- Used

- YOM:

- NA

- Control:

- NA

- Price:

- POA

- Seller:

- Muller Machines SA

- Country:

- Switzerland

DESCRIPTION

2 columns execution -Table: -

Table length - 1020 mm

Table width - 860 mm

T-channel width - 14 mm

Number of spline - 7

Distance of the T-slots - 100 mm

Table load max. - 800 kg

Longitudinal travel (X-axis) - 900 mm

Transversal travel (y-axis) - 600 mm

Verticla travel (W-axis) - 635 mm

Feeds: -

X axis - 5 - 2500 mm/min

Y axis - 5 - 2500 mm/min

W axis - 800 mm/min

Passage from grinding motor to table - 750 mm

Max. grinding diameter - 230 mm

with display-plate - 360 mm

Passage between the columns - 950 mm

Max. angle with taper grinding: -

up to - 16 °

up to grinding depth - 44 mm

Vertical travel of grinding spindle: -

up to - 180 mm

Travel speeds: -

stepless -

from - 0.015 m/min

up to - 7.5 m/min

Stroke length Z, infinitely adjustable - 125 mm

Radiale fine feed U-axis up to - 6 mm

Planetary motion speeds: c axis -

stepless -

from - 5 rpm

up to - 250 rpm

Possible grinding-spindle speeds: -

steps - 2

stepless -

from - 4500 rpm

up to - 80000 rpm

With air-turbine max. - 160000 rpm

Voltage 50 Hz3x - 380 Volt

Machine's weight about - 8000 kg

Overall dimensions machine: -

Length - 3000 mm

Width - 2570 mm

Height - 2870 - 3505 mm

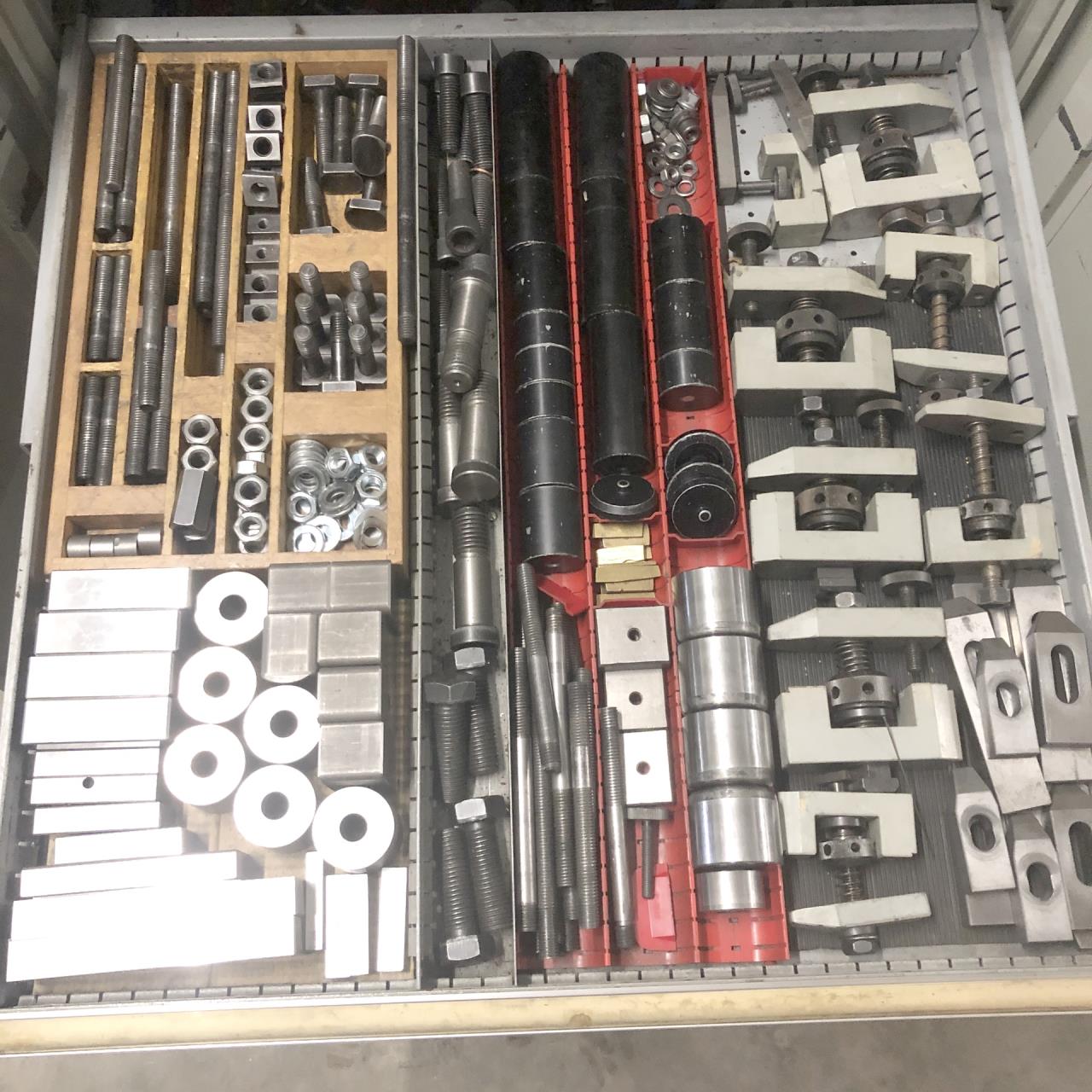

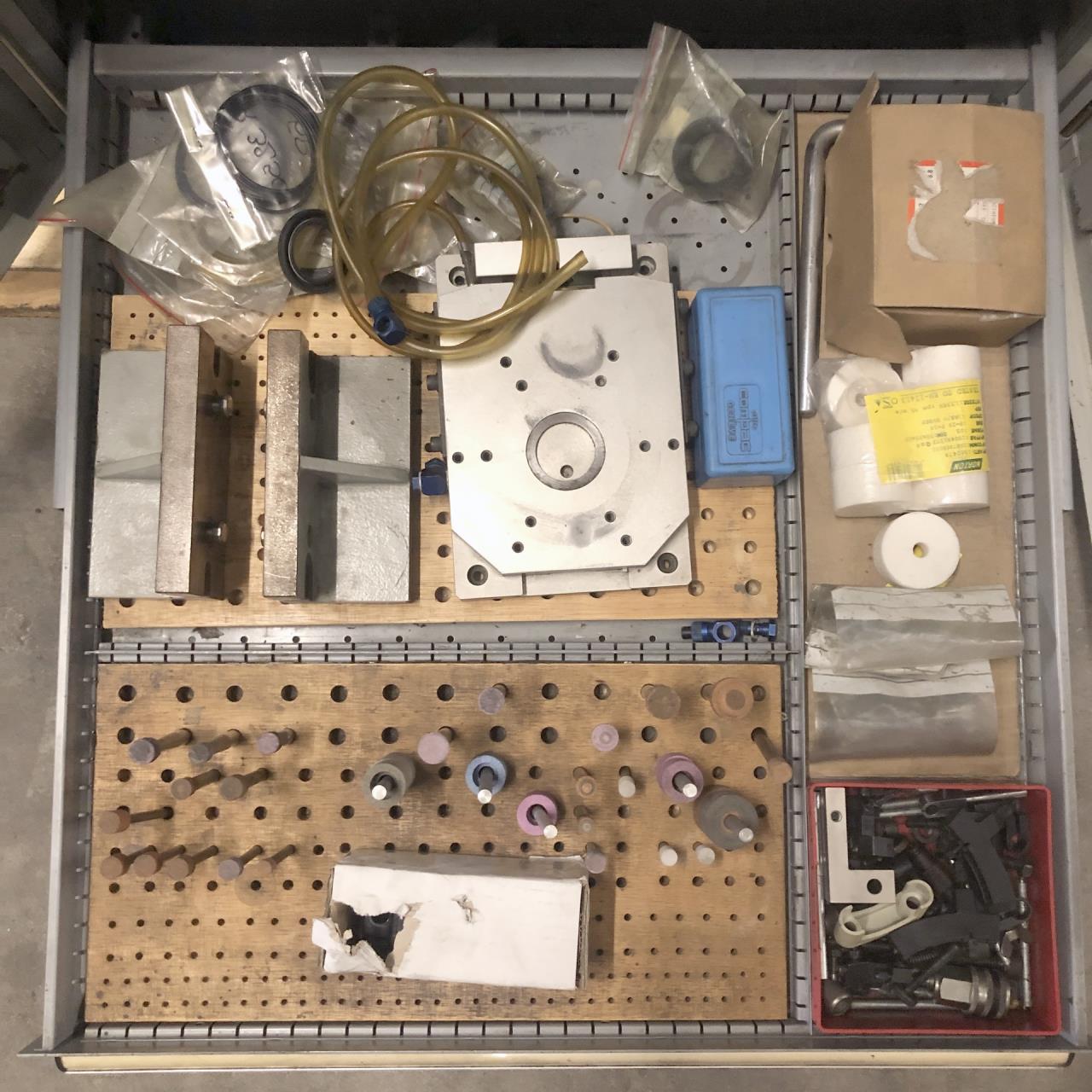

Various accessories: -

Tool cabinet -

Slot grinder -

Grinding wheel holder - 60 - 80 mm

Grinding wheel holder - 20 - 30 mm

Grinding wheel holder - 30 -50 mm

Grinding wheel holder - 50 - 60 mm

Rotary table -

Digital readout number of axis: - 2

Manufacturer - ELESTA

Centering microscop -

Redressing device with magnetic foot -

Set of grinding arbor -

Set of grinding arbors -

Grinding turbines: -

steps - 2

max. speed - 45000 rpm

max. speed - 80000 rpm

Lamp -

Set of clamping tools -

Grinding contact indicator -

Cantilever plate 45° -

Centering divice with dial indicator -

Plexi splash-guard -

Set of grinding wheels -

Angle plate -

Alignment plate -

+ request more information

SEND ENQUIRY

You may also be interested in these Machines

-

Manufacturer:Model:Description:1 column execution - Table length - 400 mmTable width - 300 mmLongitudinal travel (X-axis) - 200 mmTransversal travel (y-axis) - 200 mmTravel of the vertical slide - 250 mmPassage from grinding motor to table - 270 mmMax. grinding diameter - 15 mmVe...

-

Manufacturer:Model:Description:Year - 1990 Working area - 230 Double Column CNC Jig Grinder with ADCOS CNC 400 Ctrl.

-

Manufacturer:Model:Description:Table: - Table length - 1440 mmTable width - 860 mmTable load max. - 800 kgCarriage: - Longitudinal travel (X-axis) - 1300 mmTransversal travel (y-axis) - 800 mmVertical travel (z axis) - 635 mmPassage from grinding motor to table - 0 - 750 mmMax. ...

-

Manufacturer:Model:Description:2 columns execution - Table length - 770 mmTable width - 630 mmTable load max. - 500 kgLongitudinal travel (X-axis) - 650 mmTransversal travel (y-axis) - 450 mmVertical travel (z axis) - 500 mmSpindle stroke - 130 mmDistance from spindle-center to v...